About the Course

Rapid Prototyping is a new course offered in Vanderbilt's School of Engineering, which is required for the Digital Fabrication minor. The class is open to Vanderbilt students from Engineering, A&S, Peabody, and Blair.

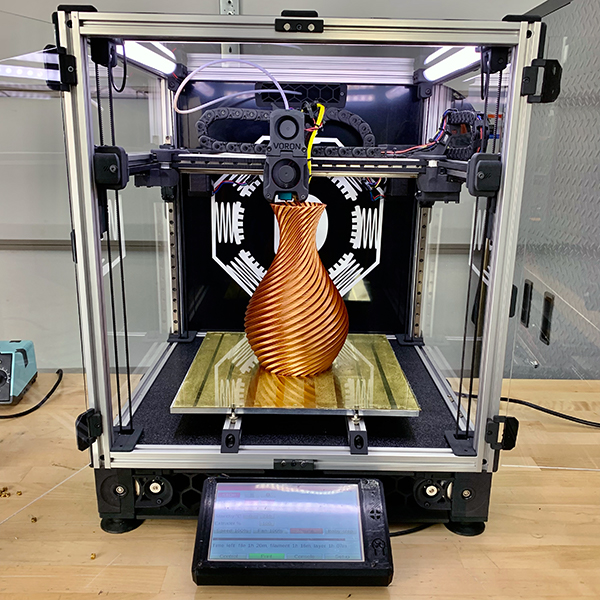

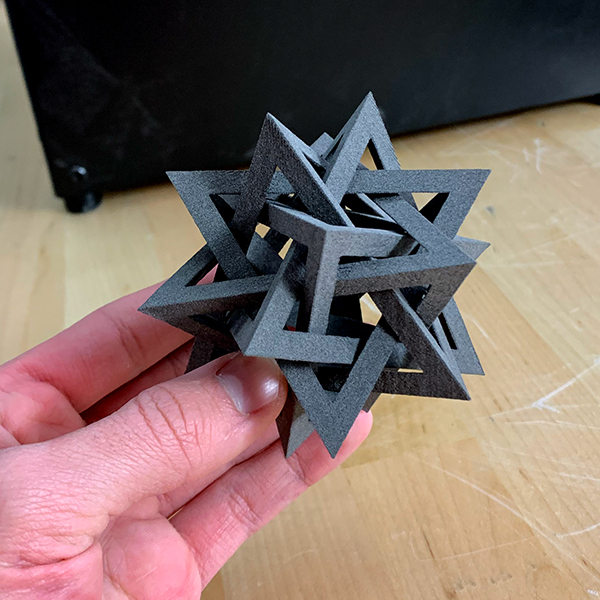

Broadly, rapid prototyping is a group of techniques that can quickly and often inexpensively fabricate a physical part. The most prominent rapid prototyping method is filament-based 3D printing. With this technique, an affordable plastic filament is liquified and deposited into a specific geometry layer-by-layer. Filament printing is accessible and requires no previous knowledge in machining or fabrication.

To unlock the capabilities of filament 3D printing and other forms of digital fabrication, a working knowledge of Computer Aided Design (CAD) is required. CAD software packages allow you to create custom 3D models, which are the input files for 3D printers. This course will cover the basics of CAD, filament-based 3D printing, and mechanical design. See the course topics below for more information.

Enroll through YES.

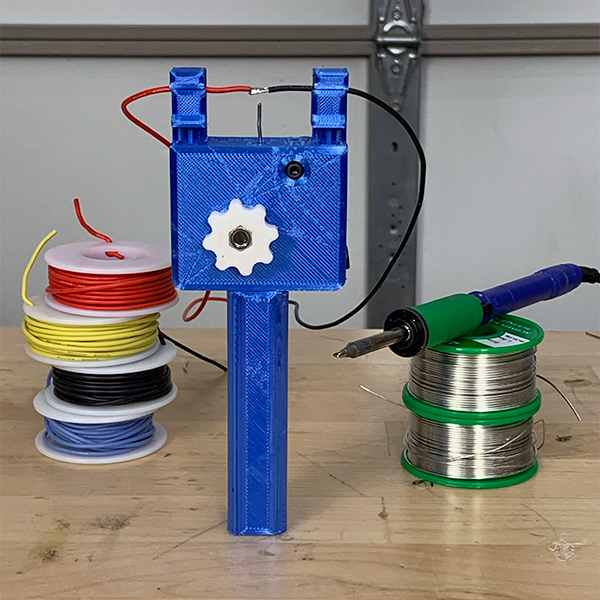

Functional Parts and Artistic Creations Made with 3D printing

Course Topics

Rapid Prototyping is a project-focused class, where the lecture material provides the skills necessary to build the final project. Currently, students are building a motorized syringe pump for the automatic delivery of small volumes of liquids. Syringe pumps are not only used in hospitals for the precise delivery of nutrients and therapeutics but are also used for depositing vicious liquids, such as gels and clay for 3D printing

To be able to design and build this final project, knowledge in 3D printing, design, and electrical prototyping is required. Explore the drop down menus below to learn about the topics covered in this course.

Measurement

How large is 1 millimeter? How accurately can we measure a millimeter? If we have a hole that is 1 millimeter in diameter, then how large of a rod should we use if we want it to fit snuggly in that hole? What about a loose fit?

Understanding how to accurately measure and select dimensions for your part are foundational skills in the design process. This course will cover measurement tools, standards, and ultimately, how to avoid creating two parts that do not fit together.

Machine Elements

When working on a new product, you do not need to reinvent the wheel. This course will cover standard components, such as fasteners (e.g., nuts and bolts), hardware (e.g., knobs and wheels), and motion components (gears and motors), that you can incorporate into your design.

3D Modeling

Manual manufacturing techniques, such as milling, turning, and molding, are time consuming and costly. Mistakes or changing design criteria can significantly increase the costs of creating physical parts through these techniques. Computer Aided Design (CAD) is the process of creating a digital model that can be tested for dimensional accuracy and mechanical strength prior to manufacturing.

A digital 3D model also contains the dimensional data needed to drive the manufacturing process (e.g., 3D printing, laser cutting, etc.). This allows you to setup the 3D printer and walk away. This course will teach the basics of 3D modeling, also known as Computer Aided Design (CAD). Students will be taught to model in Fusion 360, a CAD program by Autodesk.

Filament-Based 3D Printing

If you have ever seen a 3D printer in action, then you were probably mesmerized by how quickly and seamlessly the printer constructed the model layer-by-layer. This course will demystify the 3D printing process and provide students with all the training they need to print a variety of geometries and materials on filament-based 3D printers.Digital Logic

Sensors and microcontrollers allow your prototype to react to the world. Most consumer products incorporate some kind of digital logic, which drive LEDs, motors, and other electrical elements.

While there are many different types of sensors and microcontrollers, this class will focus on controlling simple temperature and pressure sensors with an Arduino.

Course Philosophy

Rapid prototyping by definition is all about going from idea to physical part quickly and then revising the digital model until the part matches the design constraints. To immerse students in this iterative process, they will dive into hands on projects where they will 3D print a model, test it, refine it, and reprint. Students will have access to the Digital Fabrication Makerspace and the filament 3D printers both for class projects as well as independent use.

Download the Syllabus Here

Questions?

Reach out to course instructor David Florian at [email protected]

Course instructor David Florian next to a 3D printer that he built. Students will use this 3D printer and others in the Digital Fabrication Makerspace during the course.